When you look at almost any modern product, from your car’s dashboard to the casing of your smartphone, chances are it contains plastic components made through injection molding. This process has become the backbone of mass production for plastic goods, allowing industries to create precise, durable, and cost-effective parts. But what technology drives this field? To answer that, let’s take a closer look at the machinery, processes, and innovations used by injection molding parts suppliers and plastic parts manufacturers.

Understanding the Basics of Injection Molding

At its core, injection molding is a process where molten plastic is injected into a mold cavity, cooled, and then ejected as a finished part. While this sounds simple, the technology that enables it is anything but basic. Over the years, the machinery and systems behind injection molding have evolved dramatically, blending precision engineering with automation and advanced digital control.

Suppliers in this field rely on specialized molding machines, custom-designed molds, and sophisticated software to ensure every part meets strict specifications. These aren’t just tools—they represent millions of dollars in research and development aimed at improving efficiency and quality.

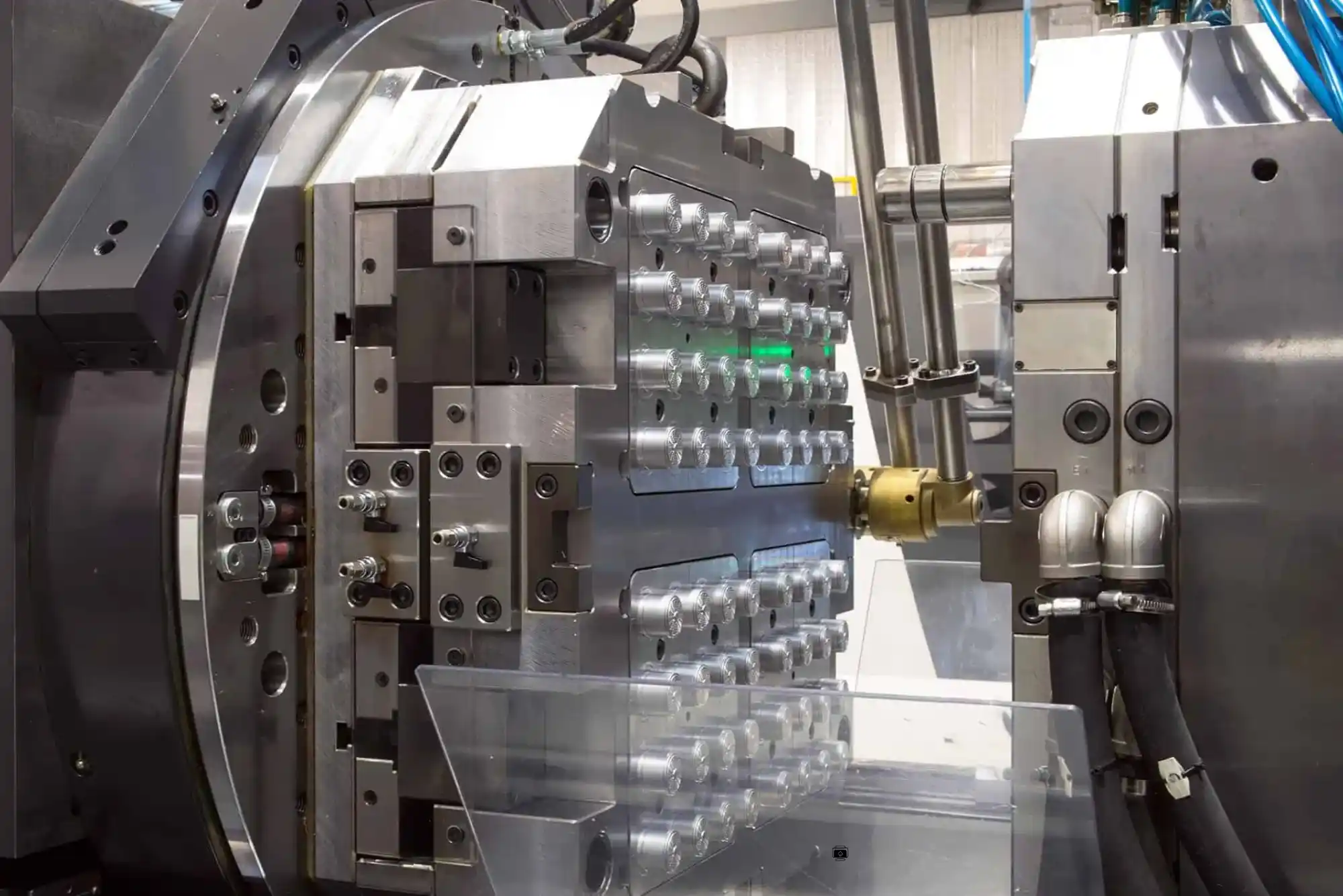

The Machinery Behind the Process

The most critical piece of technology is the injection molding machine itself. These machines are typically divided into three main types: hydraulic, electric, and hybrid.

Hydraulic machines are the traditional workhorses of the industry. They provide strong clamping forces and are often used for large parts like automotive bumpers or industrial containers. Electric machines, by contrast, are known for their precision, speed, and energy efficiency, making them ideal for smaller, high-volume production such as medical devices or consumer electronics. Hybrid machines combine the best of both, offering high clamping strength with the accuracy of electric drives.

From personal experience working with manufacturers, I’ve seen how the choice of machine can make or break a production line. For instance, a company producing intricate medical components would not risk using outdated hydraulic-only systems, as even the smallest variation could compromise safety.

Mold Technology and Design Innovations

The mold itself is a masterpiece of engineering. Molds are typically made from hardened steel or aluminum and must withstand thousands, if not millions, of cycles. Advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) software are used to create molds that allow for intricate geometries, precise dimensions, and even micro-level textures.

Modern mold technology also integrates cooling channels designed with conformal cooling methods, which allow temperature to be managed more effectively across complex mold shapes. This reduces cycle times, improves part quality, and increases overall productivity. For plastic parts manufacturers, investing in high-quality mold design is one of the most crucial steps in ensuring their competitiveness.

Automation and Robotics in Injection Molding

Another transformative area of technology is automation. Walk into a facility operated by leading injection molding parts suppliers, and you’ll see robotic arms working alongside machines. These robots handle part removal, assembly, packaging, and even quality inspections.

Automation reduces labor costs, speeds up production, and minimizes human error. But beyond efficiency, it also creates safer working conditions, as robots can handle repetitive or hazardous tasks. Some suppliers even use collaborative robots (cobots), which can safely work alongside human operators without the need for cages or barriers.

Smart Manufacturing and Digital Monitoring

With Industry 4.0 reshaping global manufacturing, injection molding is no exception. Today’s suppliers often integrate sensors and Internet of Things (IoT) systems into their machines. These sensors collect real-time data on temperature, pressure, and cycle times, which is then analyzed through software platforms.

This digital monitoring enables predictive maintenance, ensuring machines are serviced before they break down. It also helps optimize production runs, reducing material waste and energy consumption. For companies producing high-value parts, these systems provide peace of mind, knowing that each component is being manufactured within exact tolerances.

Material Science and Resin Technology

The success of injection molding doesn’t just rely on machinery—it also depends on the materials used. Over the years, advancements in polymer science have given plastic parts manufacturers access to resins with remarkable properties. From heat-resistant polymers for automotive engines to biocompatible plastics for medical implants, material choice is now a critical part of the design process.

Suppliers often work closely with chemical companies to test and validate new materials, ensuring they meet the performance requirements of specific industries. This collaboration drives innovation, opening doors for lighter, stronger, and more sustainable products.

Quality Control and Testing Technology

Injection molding suppliers cannot afford to compromise on quality. That’s why they rely on advanced testing and inspection technologies. Techniques like coordinate measuring machines (CMM), laser scanning, and even X-ray analysis are used to confirm that parts meet precise dimensions and structural integrity.

In some industries, like aerospace or healthcare, the stakes are even higher. Here, rigorous testing ensures that every single component complies with regulatory standards before it reaches the market. From my perspective, this emphasis on quality is what separates reputable suppliers from those who cut corners.

Sustainability and Eco-Friendly Technologies

With growing global awareness of environmental issues, suppliers are also adopting greener technologies. This includes energy-efficient electric machines, recyclable materials, and closed-loop water cooling systems to conserve resources. Some injection molding parts suppliers are even experimenting with biodegradable polymers and post-consumer recycled plastics.

This shift is not only good for the planet but also aligns with customer demand. Many brands want to highlight eco-friendly practices in their supply chain, and suppliers who adopt these technologies gain a competitive edge.

The Human Element Behind the Technology

While machines and software play a vital role, we can’t forget the people who operate them. Skilled technicians, engineers, and designers bring human expertise into the mix. They interpret data, troubleshoot issues, and ensure production runs smoothly.

In my interactions with suppliers, I’ve noticed that those who invest in training and workforce development often deliver better results. Technology may provide the tools, but it’s the human element that ensures they’re used to their full potential.

Why Technology Matters for Clients

For businesses that rely on molded parts, choosing the right supplier often comes down to the technology they use. Advanced machinery and systems translate to faster production, consistent quality, and lower overall costs. Whether a company is sourcing parts for electronics, automotive, or consumer goods, working with technologically advanced plastic parts manufacturers can mean the difference between success and failure.

This is why many clients conduct audits of supplier facilities before signing contracts. They want to see not just the machines, but also the processes, certifications, and digital systems in place. It’s a form of assurance that their products will be delivered on time and to the highest standards.

Final Thoughts

Injection molding has come a long way from its early days. Today, the field is defined by a mix of advanced machinery, robotics, digital monitoring, and material science. For injection molding parts suppliers and plastic parts manufacturers, technology is not optional—it’s the foundation of their business.

As industries demand more complex, precise, and sustainable parts, suppliers will continue to push the boundaries of what’s possible. And for clients, understanding the technology behind injection molding is key to making informed decisions when selecting partners.

In the end, it’s not just about machines—it’s about how technology, materials, and human expertise come together to shape the products we use every day.